Related Technologies

With cooler temperatures now common in many parts of North America and winter just around the corner, the belief in the importance of R-Value becomes a regular topic of conversation for owners, architects, designers, builders and tenants of both residential and commercial buildings. Unfortunately, R-Value is only a small part of the building efficiency and operating cost story.

A far more important factor for consideration when outside temperatures are dramatically different than desired internal temperatures (not to mention relative humidity) is the effect of thermal bridging on R-Value. With energy costs continuing to increase, the importance of reducing thermal bridging to both keep your building cool and warm in the face of cold winters and hot summer weather is critical.

What is Thermal Bridging?

A thermal bridge, also called a cold bridge, heat bridge, or thermal bypass is an area or component of an object which has a higher thermal conductivity than the surrounding materials, creating a path of least resistance for heat transfer[i]. Thermal bridging can be magnified by details such as non-continuous insulation, gaps, connection details and common structural elements such as steel and wood studs.

Thermal bridging, in addition to heat transfer, may cause building materials to absorb water/humidity and cause condensation, which in turn can result in mold growth, corrosion and deterioration of the building envelope. It’s not just that draft of cold air you feel in an old building, but the metal stud or air gap in the insulation conducting cold or hot temperatures through the building envelope.

Reducing thermal bridging by specifying better building materials such as engineered wall systems with continuous insulation significantly reduces thermal bridging, which in turn saves money, both in the short term and long term. Understanding R-Value and ‘Effective R-Value’ is also an important part of the building efficiency conversation.

What is R-Value?

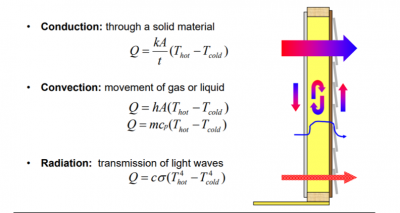

Quite simply, R-Value, or thermal resistance, is a material’s ability to resist heat flow. Heat and cold transfer through a building envelope at different rates depending on materials. R-Value is the measure of that transfer through a solid material.

Figure 2. Three modes of heat transfer through wall conduction (R-value), convection (air infiltration) and radiation

Too often, people focus on nominal R-Value, which is the R-Value of a material tested in optimum lab conditions vs. effective R-Value, which is the actual performance in real conditions. Too often, we are led to believe in a material’s nominal R-Value. This “estimated” level of performance may change dramatically during cold winter months and is highly dependent on building assembly and specifications.

Structurally engineered panels with enclosed/encapsulated studs and continuous high-performance insulation that does not deteriorate over time provide a significantly higher Effective R-Value throughout the range of exterior temperatures.

Other Considerations

The push for net-zero and higher performance buildings is growing. When done right, this should result in significant cost savings for owners with the added benefit of increased longevity for their structures. The reduction of thermal bridging and utilization of higher effective R-Value materials are key to achieving these goals. One additional factor for consideration in choosing appropriate building materials is thermal mass. Building materials such as cement, tile and bricks have high thermal mass, while materials such as timber have low thermal mass. High thermal mass materials mitigate large temperature swings due to thermal bridging and low effective R-Value.

MgO Systems C3 Engineered Wall System™ is a high-performance engineered wall system that significantly reduces thermal bridging and is tested to a higher effective R-value than conventional building materials. Further, the C3 Engineered Wall System™ has a higher thermal mass than conventional building materials. So, in addition to having superior resistance to fire and mold and extreme weather events, it will reduce operating costs and extend the longevity of your building.

MgO Systems: Faster, Stronger, Safer…and, more cost-effective!

[i] Binggeli, C. (2010). Building Systems for Interior Designers. Hoboken, NJ: John Wiley & Sons.

[ii] Progressive Foam, 2018. What is thermal bridging, and how to stop it in a https://progressivefoam.com/thermal-bridging-and-how-to-stop-it/(accessed Oct. 5, 2019)

[iii] Richard S. Duncan, 2008. Effects of Temperature and Air Infiltration on Thermal Performance of Insulation and Insulated Frame Wall Assemblies.

|

No Results

|

|

No Results

|

Are you sure you want to do this?